Gravitational Wave Observations

Gravitational-wave astronomy pioneered by advanced technology development

Observing extremely weak gravitational waves from space can unveil new aspects of the Universe inaccessible by conventional astronomy. The Advanced Technology Center is in charge of designing and manufacturing key components such as optical equipment and vibration isolators for KAGRA, a large-scale cryogenic gravitational-wave telescope in Japan.

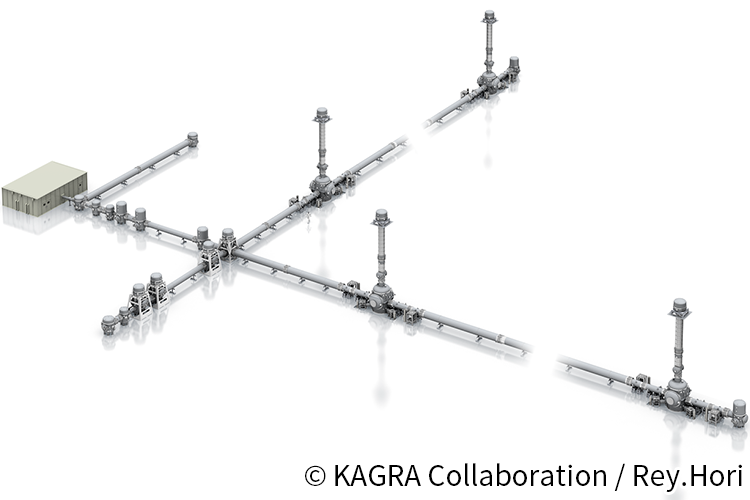

KAGRA

KAGRA is an international gravitational-wave observatory hosted by the Institute for Cosmic Ray Research, University of Tokyo, together with the National Astronomical Observatory of Japan and High Energy Accelerator Research Organization, as well as numerous other international institutes and universities. It is the first large-scale gravitational-wave telescope in Japan, being located under Mt. Ikenoyama, Kamioka-cho, Hida, Gifu prefecture. Unlike conventional "telescopes," this is a large-scale Michelson interferometer having two 3-km long arms installed within a vacuum vessel in an L-shaped tunnel excavated under the mountain.

Gravitational waves are propagating, periodic, weak space-time distortions. In order to achieve sufficient sensitivity to such tiny signals, we need to isolate the optics in the interferometer from noise of all kinds. For this reason, we have constructed the interferometer at a stable site with low ground vibrations (less than one-100th that of Tokyo) and suspended the mirrors from vibration isolators made of multi-stage pendulums. The most significant mirrors are cooled to nearly -250℃ to suppress thermal noise.

The Advanced Technology Center applied technological capabilities accumulated during the development of other types of telescopes and detectors to the design, production, and installation of various components that enabled the KAGRA interferometer to become what it is today. These components include opto-mechanical systems to monitor the 3-km-long laser optical beam axes, stray light countermeasures, and vibration isolators. We also contribute to developing new sapphire mirrors, which will be necessary for KAGRA's next goal of improving performance.

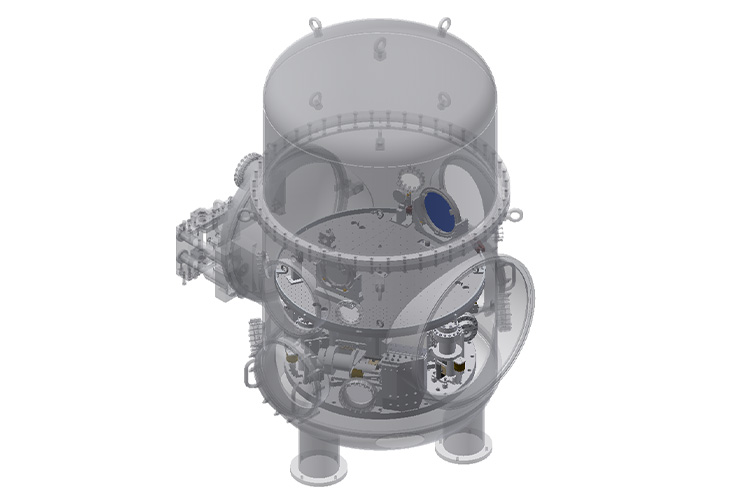

Transmission Monitors

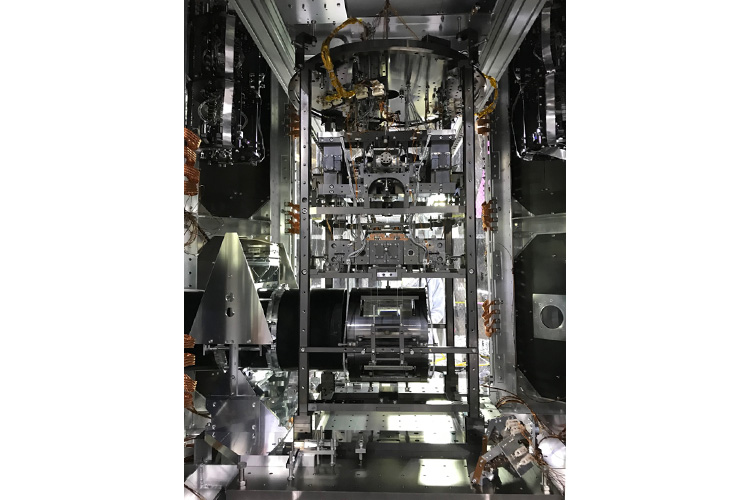

Systems to detect mis-alignment of the optical axes in the 3-km-long laser cavities. The Advanced Technology Center has been involved in the entire process from design to assembly, testing, and onsite installation.

Optics

The design is based on a transmission telescope. The optical axis is folded to achieve a reduction ratio of 1/10 within a 1-m diameter vacuum vessel.

Vibration Isolator Part

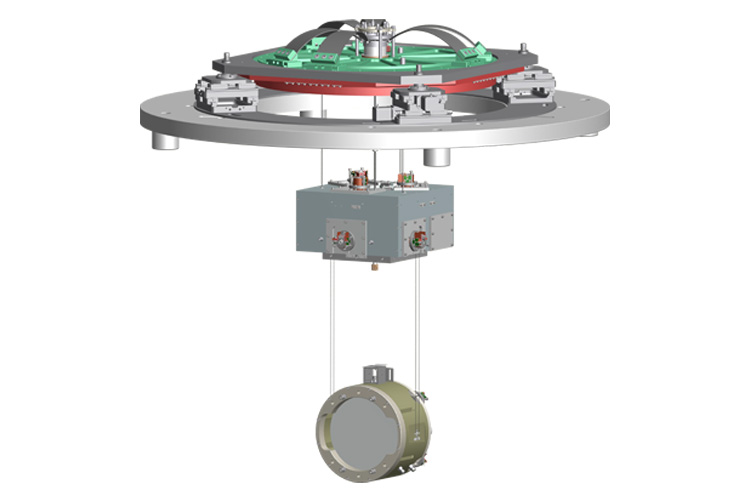

This part is a combination of passive vibration isolation using a pendulum and active vibration damping using various onboard sensors and actuators.

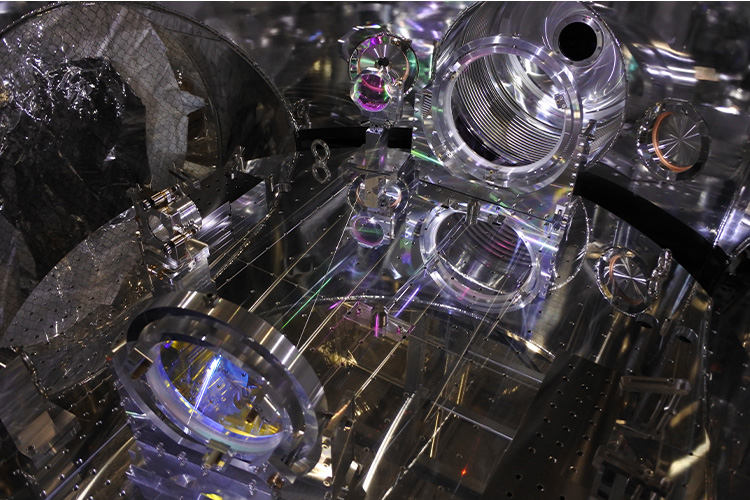

Stray Light Countermeasures

In gravitational-wave telescopes, the basic stray light countermeasure is to install optical baffles to block the stray light. The Advanced Technology Center has contributed to the design and fabrication of these optical baffles.

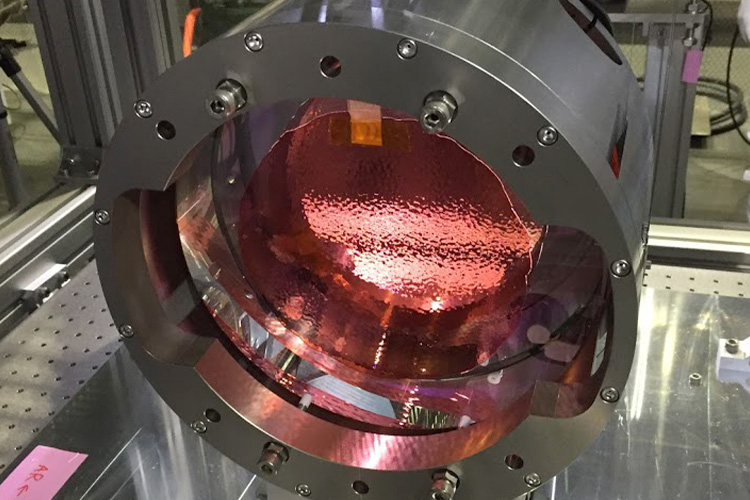

This photo shows the inside of a cryostat containing a main mirror for KAGRA. The main mirror is hanging in the lower center of the image; to the left, part of the baffle to block unwanted light scattered from the mirror can be seen. This baffle is on a vibration isolator as well.

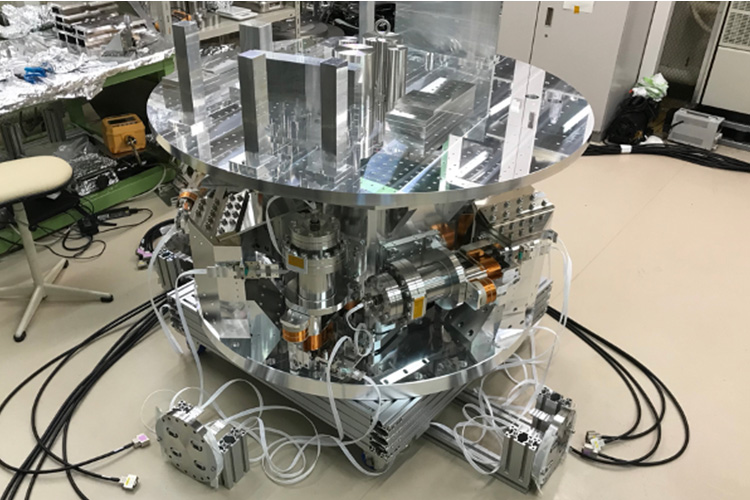

Mirror Suspensions

To isolate the mirrors in the main path of the laser interferometer from seismic perturbation, they are suspended from multi-stage pendulums.

Vertical Vibration-Isolation Filter

Using a GAS (geometric anti-spring) mechanism combining multiple plate springs made of maraging steel, we realized a vertical spring pendulum that can withstand large deformations and loads with a long-period (>2.5 seconds).

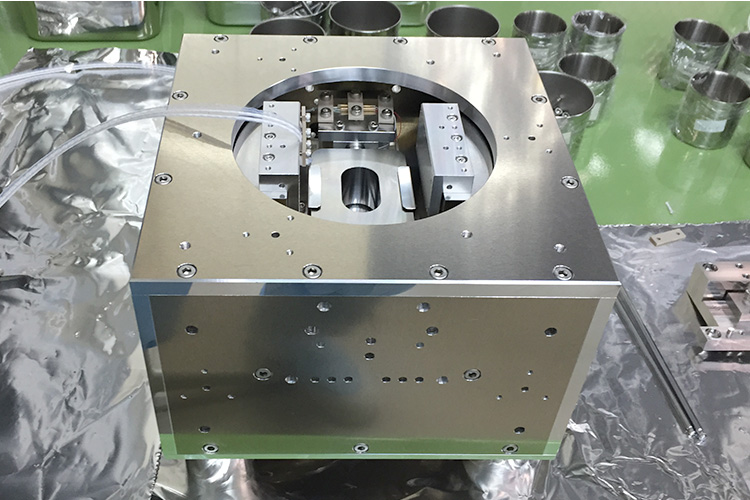

Intermediate Mass

This is equipped with a mechanism to change the center of gravity to achieve balance, as well as various sensors and actuators.

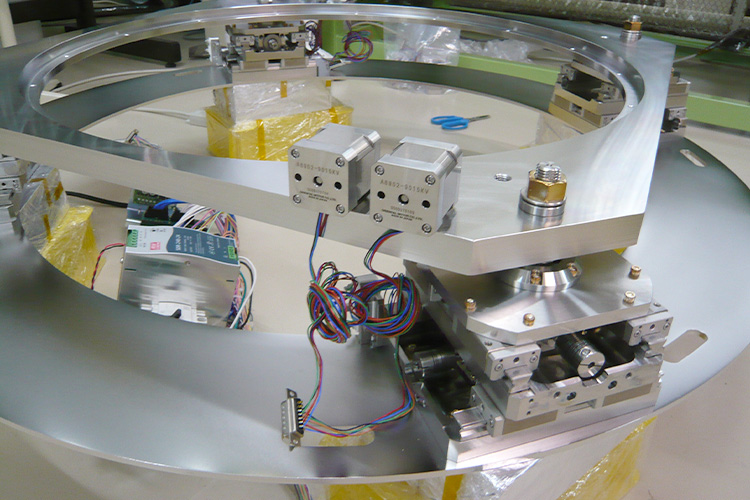

Travserser

This is equipped with a mechanism to smoothly translate and rotate the equipment in vacuum, while supporting the large mass of the vibration isolator hanging below. The vertical vibration-isolation filter explained above is mounted on top of this device.

Recoil Mass and Mirror

The recoil mass is used to balance against the suspended mirror's motion, and is shaped to surround the mirror. It was manufactured from 64 titanium, taking into account several benefits including electrical conductivity. It is shown in the photo together with the inner mirror. (The red film on the mirror is to protect the surface of the mirror from dust and dirt.)