Fabrication

This department is in charge of manufacturing parts for experimental and observation equipment.

The Machining team, Additive Manufacturing team, and Measurement team work together to support equipment development through fabrication.

Team Overview

Manufacturing team

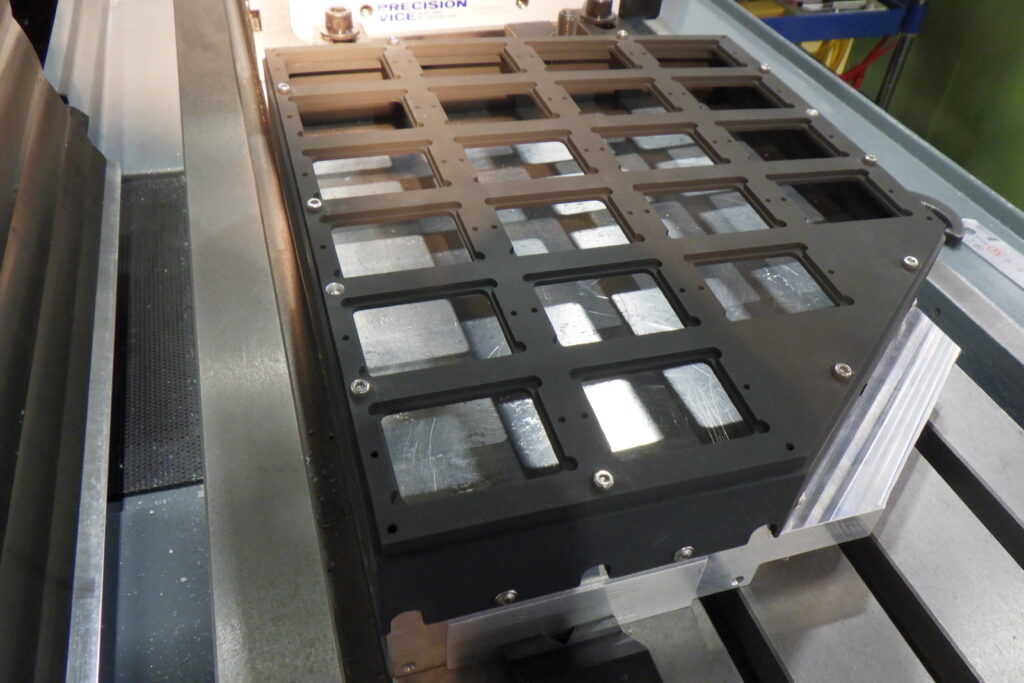

We use machining centers, milling machines, lathes, electric discharge machines, and various other machine tools to manufacture observational devices and other equipment.

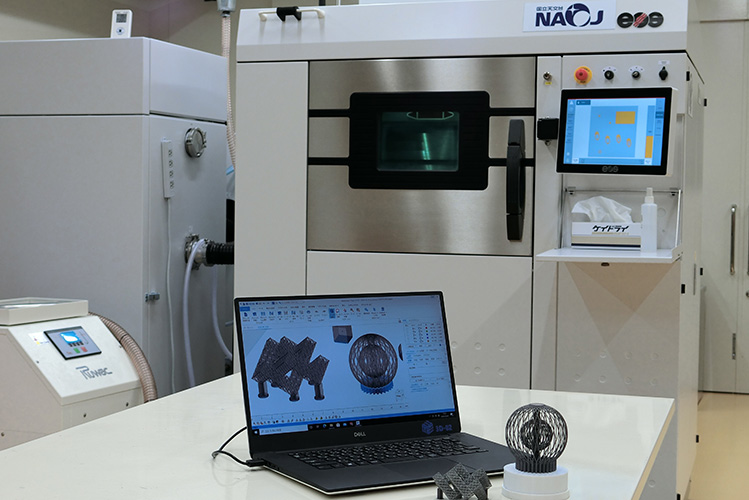

Additive Manufacturing team

We are currently developing applications of additive manufacturing technology for astronomical observational equipment using metal and plastic 3D printers.

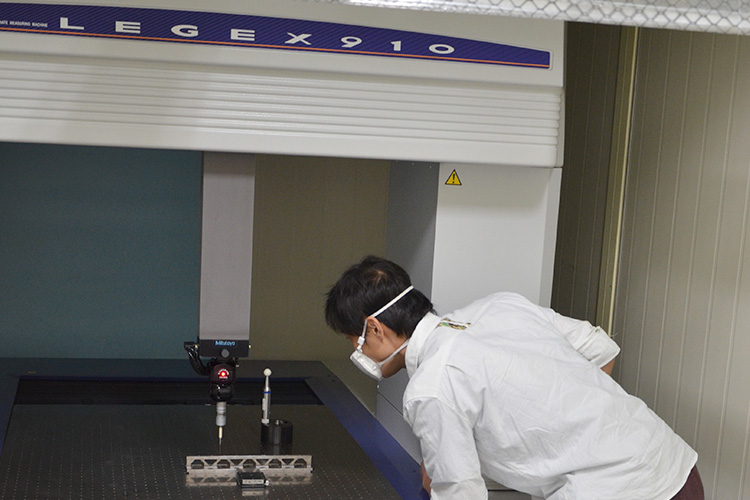

Measurement team

We perform precision measurements such as shape measurements of machined parts, position measurements for assemblies, and alignment adjustment of optical equipment.

Manufacturing Design Group's YouTube Channel

Machine List

The Manufacturing and Design Group supports the development of astronomical instruments and experimental equipment through "manufacturing," mainly metalworking by our three teams that perform machining and ultra-precision machining; metal 3D printing; and precision measurement.

Main Machines

5-axis Machining Center

Metal 3D Printer (Powder bed fusion type)

Wire Electrical Discharge Machine

Ultra-Precision Machine Tool

Three-Dimensional Measurement System

Example Products

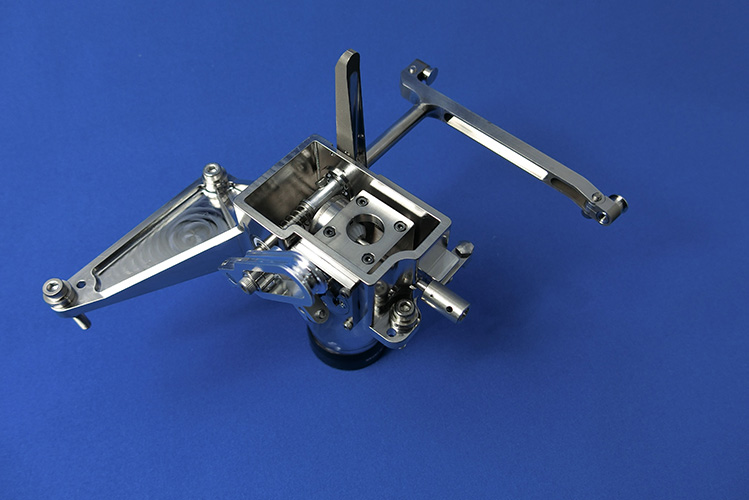

Pick-off Mirror Drive Mechanism

(TMT/InfraRed Imaging Spectrograph)

Material: Invar 36 (FN-36)

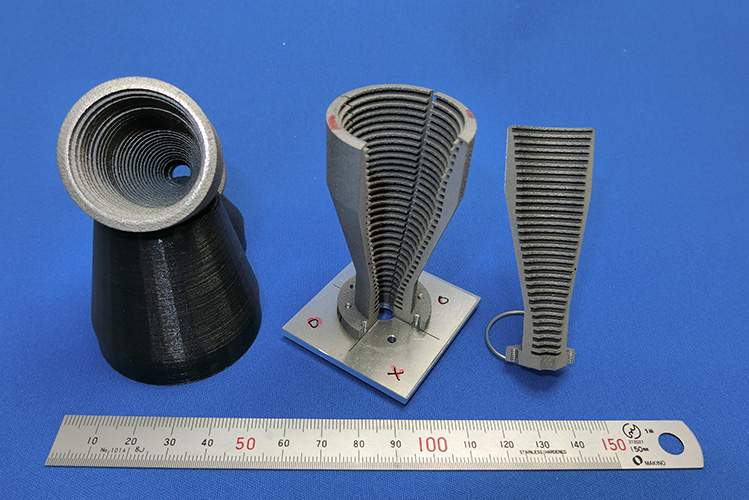

Corrugated Horn, Fabricated by Metal 3D Printer

(ALMA receiver parts)

Material: AlSi10Mg

Circle-Square Conversion Waveguide

(Experimental Parts)

Material: Aluminum alloy

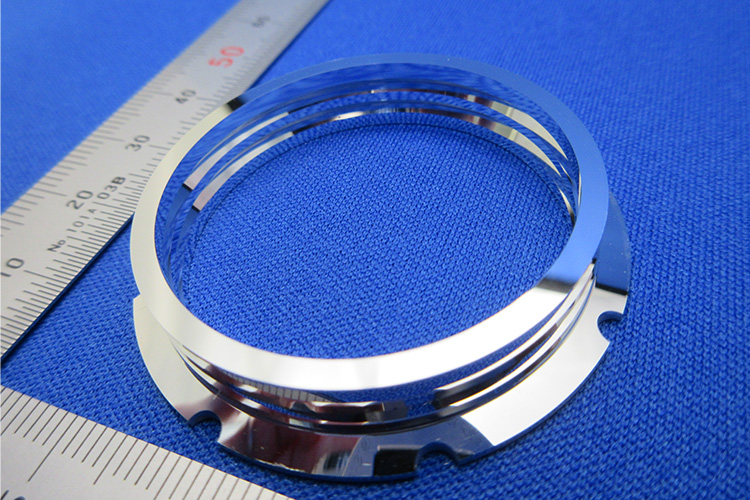

Lens Retainer with Heat-sink Capability

SUNRISE-3, third flight of the international balloon project SUNRISE

Material: Aluminum alloy

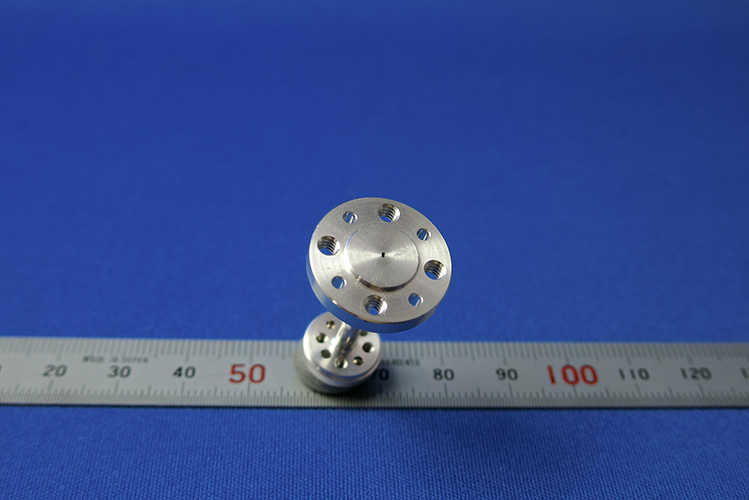

Monolithic Kinematic Mirror-mount with Stress-relief Function

Solar-observing sounding rocket experiment CLASP (Chromospheric Lyman-Alpha Spectro-Polarimeter)

Material: Super invar (FN-315)

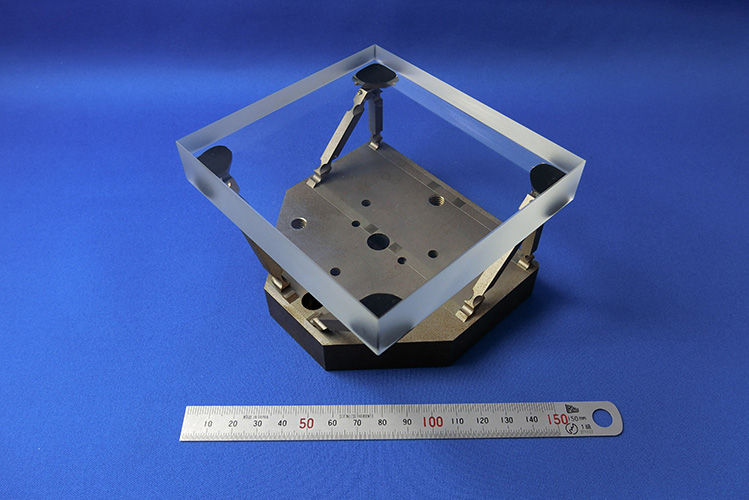

Filter holder for Tomo-e Gozen camera for Kiso Schmidt telescope, University of Tokyo (Kiso Observatory, The University of Tokyo)

Material: AlSi10Mg